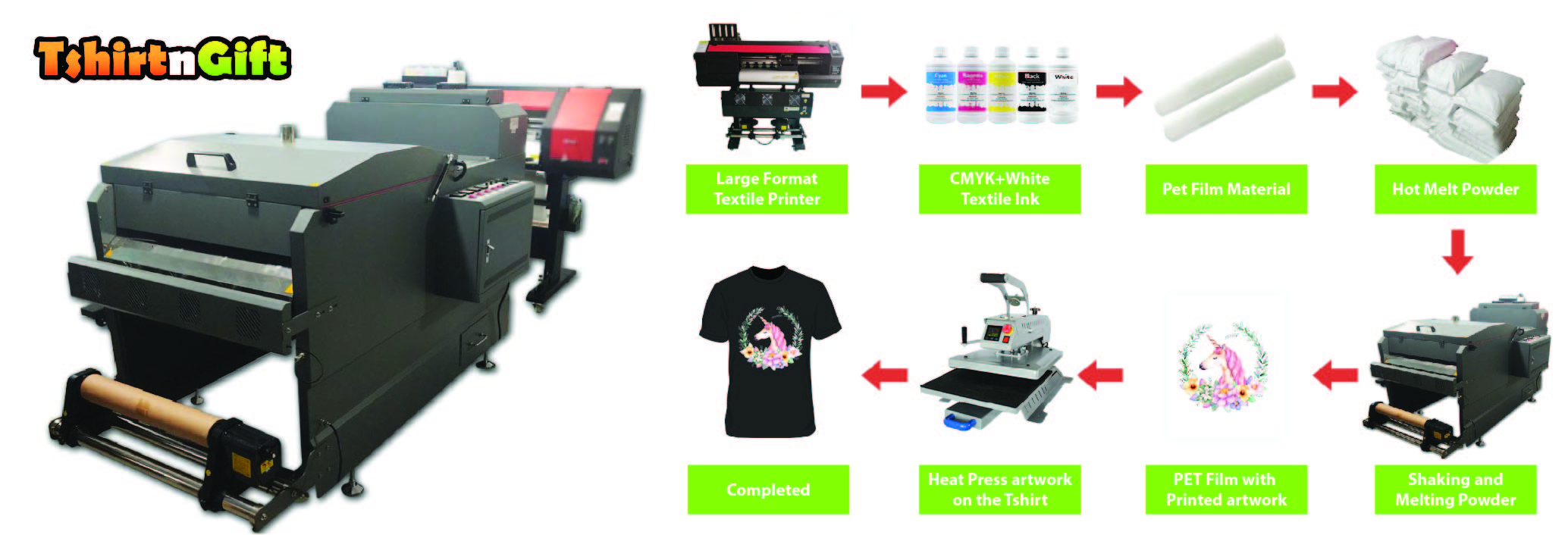

DTF is a revolutionary new printing technique that's more affordable and accessible compared to DTG, screen printing, sublimation or laser white toner transfers. DTF required a special printer and DTF ink to print the image on PET transfer film. With DTF you can transfer to 100% cotton shirts without pre-treatment, saving a lot of money and time. DTF is washable unlike laser toner transfers and it feels a lot better to the touch.